AutomationDirect.com specializes in providing a wide range of electric motors to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower industries to optimize their operations...

Since our inception in 1932, Carter Motor manufactures AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, and many others. All of our products are designed and assembled here in the USA. Our team is here to help you determine the best motor to fit your application and to ensure the process is efficient and stress-free. We are...

The products of Composite Motors, Inc. all undergo the same AS9100 certified design, manufacture and testing protocol. These products include Brushless DC motors, motor drivers, Lithium Ion batteries and Battery Management Systems, gear motors and linear actuators. All products are made in the USA from raw materials. Visit our website to learn more and to view our newest products.

We manufacture motors, motion control and rotating products for OEMs. The electric motors obtainable through us include AC motors, AC/DC motors, brushless DC motors, stepper motors.

At Electric Motor solutions, our goal is to provide the best motors and equipment to meet the needs of your application. Products include linear actuators, electric motors, speed reducers, custom motors, vacuum cleaner motors, AC motors, and more.

At Allied Motion Technologies, Inc., we pride ourselves on being at the forefront of innovation in the electric motor industry. Our extensive portfolio encompasses a diverse range of electric motors designed to meet the evolving needs of various applications. From precision-engineered brushless DC motors to high-performance stepper motors, we offer solutions that deliver exceptional reliability...

At Johnson Electric, we stand at the forefront of innovation in the electric motor industry, dedicated to delivering exceptional products and services that meet the diverse needs of our global clientele. Our expertise lies in the design, manufacturing, and optimization of high-performance electric motors that power a wide array of applications, from industrial machinery to consumer electronics.

More 3 Phase Motor Manufacturers

A 3-phase motor refers to an electrical-to-mechanical energy conversion mechanism that can convert an input of 3-phase electrical power to produce an output of mechanical energy.

What Is a 3-Phase Motor?

The motor consists of a rotating rotor and a stator. The stator winding receives the 3-phase supply of electrical energy and drives the rotor windings through electromagnetic induction.

How 3-Phase Motors Function

As the 3-phase stator winding receives a balanced supply of 3 phase electrical energy, a rotating magnetic field is produced in the motor. The rotating magnetic field rotates around the stator at a synchronous speed that is denoted by:

Synchronous speed = 120 f / P

Where f is the frequency of rotation and P is the number of poles.

Since the rotors carry a current and are in the magnetic field produced by the stator winding, they experience a mechanical force. The combined forces experienced on all the rotor conductors result in a torque which drives the rotors in the direction of the rotating magnetic field.

Types of 3-Phase Motors

There are two main types of 3-phase motors: the squirrel cage and the slip ring motors. The differences are mainly based on rotor windings.

Squirrel Cage Motor

The structure of this rotor assembly resembles the shape of a squirrel cage. The construction is simple and rugged and consists of a cylindrical laminated core rotor with slots on the external periphery. The squirrel cage has rotor bars instead of the expected rotor windings.

The bars are made of aluminum, copper, or brass. The rotor bars are welded or braced with the end rings for mechanical support. Normally the bars are short-circuited to add external resistance to the circuitry. This type of motor does not use slip rings or brushes, making construction simpler and very robust.

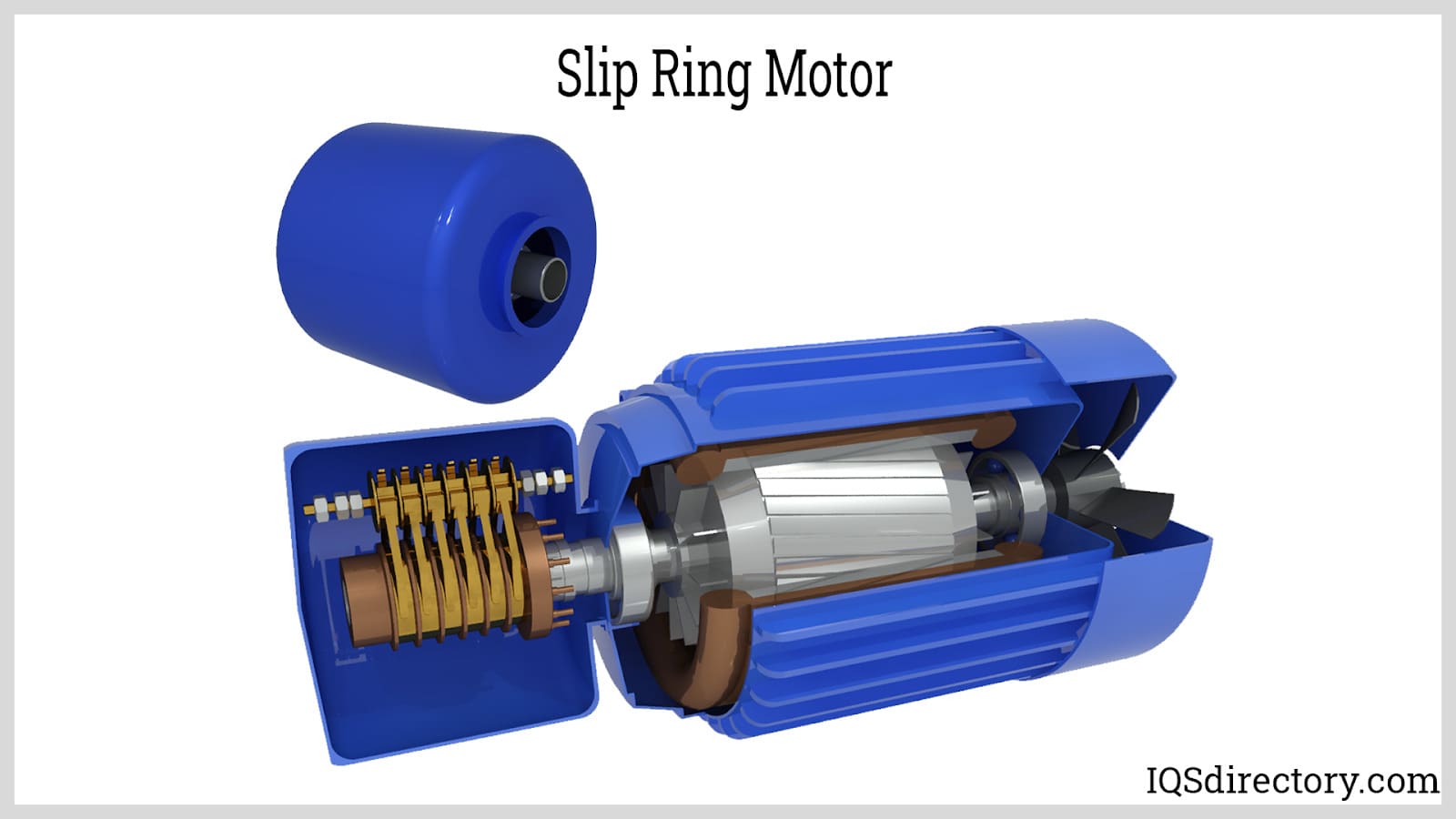

Slip Ring Motor

Slip ring induction motors are also referred to as wound motor rotors. It consists of a laminated cylindrical core with slots on the outside periphery and the rotor winding placed within them. The winding is wound so the number of poles in the rotor winding is equal to the stator winding. The end terminals of the rotor windings are then connected to the slip rings. An external resistance can be connected easily to the rotor circuit through the brushes and slip rings. This is important in controlling the speed and torque of the motor.

Applications of 3-Phase Motors

Slip ring motors are usually used for devices like plunger pumps, cranes, conveyors, crushers, or elevators. In addition, slip ring induction motors are commonly used for loads that need a very high initial torque and usually for cases where the starting current is low. They are also ideal for the carriage of loads that require speed control and altering the spin rate. Squirrel cage motors have a normal initial torque with a high starting current. The motors are commonly used in appliances like electric blowers, fans, and centrifugal pumps.

Advantages of 3-Phase Motors

- 3-phase motors have a simple and rather rugged construction. Once set up, they do not require extensive maintenance and are therefore less expensive.

- 3-phase motors have very high efficiency and a favorable power factor. Thus, for a given load, they draw fewer volt-amperes.

- 3-phase motors also have a self-starting torque.

- These types of motors, if accurately set, can be left out to work automatically without the need for human control but rather scheduled maintenance after a specified duration.

- Typical examples are the case of conveyor belts and building elevators that can function automatically without constant control.

- Single-phase systems can yield pulsating power, but 3-phase systems yield a more stable power supply.

Choosing the Correct 3-Phase Motor Supplier

For the most productive outcome when purchasing a 3-phase motor from a 3-phase motor supplier, it is important to compare several 3-phase motor suppliers using our directory of 3-phase motor companies. Each 3-phase motor supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each 3-phase motor business website using our proprietary website previewer to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple 3-phase motor companies with the same form.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services