AutomationDirect.com specializes in providing a wide range of electric motors to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower industries to optimize their operations...

Since our inception in 1932, Carter Motor manufactures AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, and many others. All of our products are designed and assembled here in the USA. Our team is here to help you determine the best motor to fit your application and to ensure the process is efficient and stress-free. We are...

The products of Composite Motors, Inc. all undergo the same AS9100 certified design, manufacture and testing protocol. These products include Brushless DC motors, motor drivers, Lithium Ion batteries and Battery Management Systems, gear motors and linear actuators. All products are made in the USA from raw materials. Visit our website to learn more and to view our newest products.

We manufacture motors, motion control and rotating products for OEMs. The electric motors obtainable through us include AC motors, AC/DC motors, brushless DC motors, stepper motors.

Glentek, Inc. is a trusted provider of high-performance electric motors, specializing in innovative motion control solutions for a wide range of industries. We design and manufacture precision servo motors and amplifiers, delivering powerful and efficient performance for demanding applications. Our engineering expertise allows us to develop both standard and custom solutions, ensuring that each...

A leading supplier of high-performance motors and components, Chiaphua Components North America serves customers throughout the Americas and offers electric motors through the CCL & CIM Motor Products division. We supply motor solutions such as brushless motors, permanent magnet DC motors, induction motors, shaded pole motors, universal motors, vacuum cleaner motor, & gear motors.

More 3 Phase Motor Manufacturers

A 3-phase motor is an advanced electrical device engineered for converting three-phase electrical power into mechanical energy. These motors are widely used in industrial and commercial applications due to their efficiency, reliability, and ability to handle high power loads. If you’re seeking consistent, robust, and efficient rotary power for your machinery, understanding the fundamentals of 3-phase motors is essential.

What Is a 3-Phase Motor?

A 3-phase induction motor consists primarily of two main parts: a stationary stator and a rotating rotor. The stator contains windings that receive a balanced three-phase supply of alternating current (AC) electrical energy. Through the principle of electromagnetic induction, the stator creates a rotating magnetic field that induces current in the rotor, resulting in torque and mechanical rotation. This configuration has made three-phase motors the backbone of modern automation, manufacturing, and process industries.

How 3-Phase Motors Function

When the stator windings of a three-phase AC motor receive a balanced supply, they produce a rotating magnetic field inside the motor. This field rotates around the stator at what is known as the synchronous speed, calculated as follows:

Synchronous speed = 120 f / P

Where f is the supply frequency (in Hz), and P is the number of poles in the stator.

As the rotor conductors are placed within this magnetic field, they experience an induced electromotive force (EMF) according to Faraday’s Law. This EMF generates a current within the rotor, which in turn interacts with the magnetic field to produce a mechanical force. The combined mechanical forces on all rotor conductors create the torque necessary to drive the rotor in the direction of the rotating magnetic field. This self-starting feature and the ability to produce constant torque make three-phase motors highly desirable for continuous duty operations.

Key Features of 3-Phase Motor Operation

- High starting torque—ideal for demanding industrial loads.

- Stable and consistent rotation—minimizes vibration and ensures smooth performance.

- Self-starting mechanism—no need for additional components or manual intervention.

- Efficient energy conversion—lower losses compared to single-phase motors.

Types of 3-Phase Motors

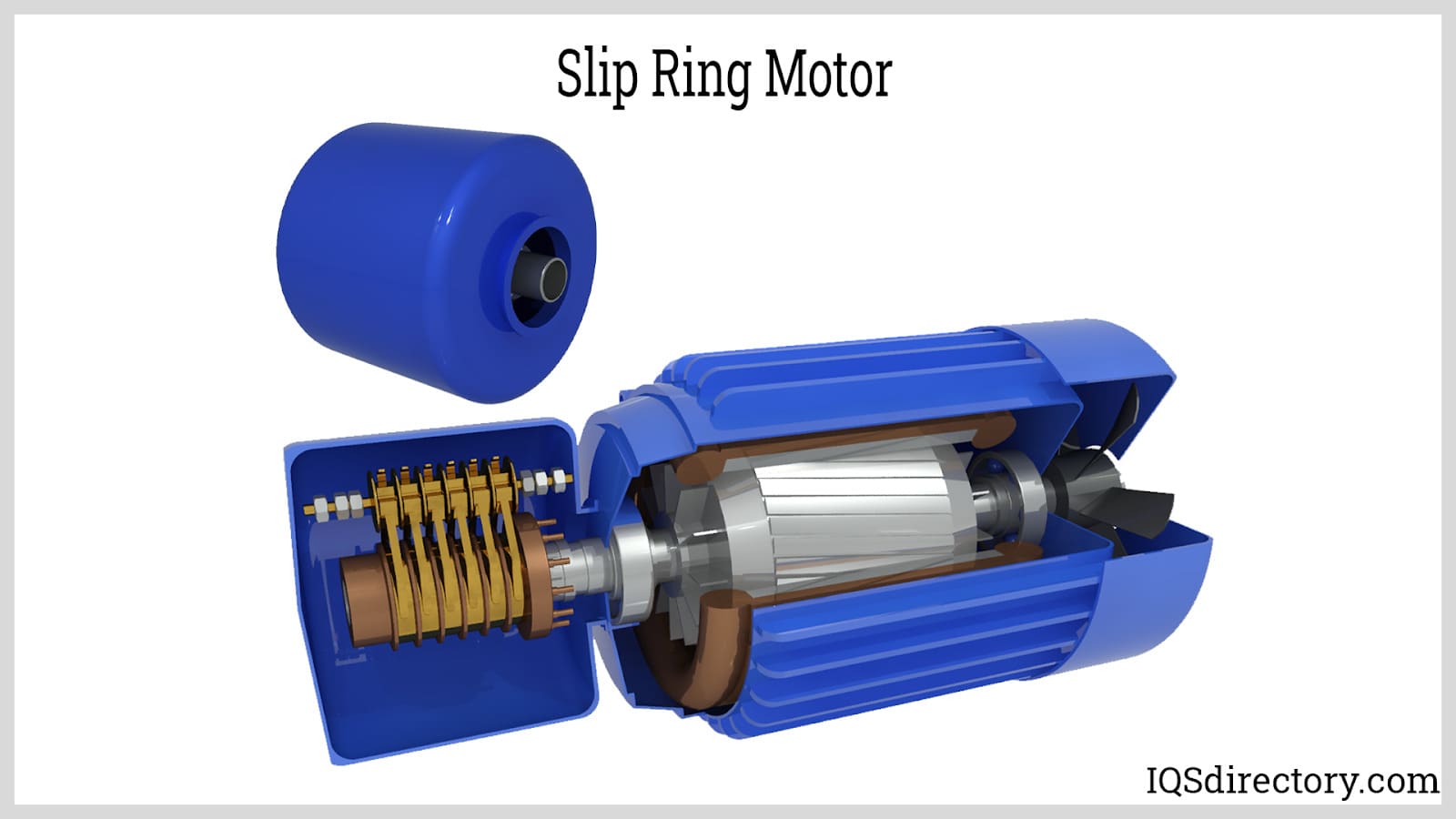

There are two main types of three-phase induction motors: the squirrel cage motor and the slip ring (wound rotor) motor. Each type is suited to specific applications and operational requirements. Understanding the distinctions can help you choose the right motor for your project or facility.

Squirrel Cage Motor

The squirrel cage induction motor is the most widely used type of three-phase motor in industry. Its rotor assembly resembles a cylindrical cage, hence the name. The construction is simple, rugged, and reliable, consisting of a laminated iron core with slots on the external periphery. Instead of traditional windings, the rotor contains bars—typically made of aluminum, copper, or brass—short-circuited by end rings.

This design eliminates the need for slip rings or brushes, reducing maintenance and increasing durability. Squirrel cage motors are especially suitable for applications requiring minimal start-up control and consistent operation, such as fans, blowers, compressors, and centrifugal pumps.

Advantages of Squirrel Cage Motors

- Simple construction and robust performance

- Low cost and minimal maintenance requirements

- High efficiency and excellent reliability

- Suitable for most standard industrial and commercial uses

Slip Ring Motor (Wound Rotor Motor)

Slip ring induction motors, also called wound rotor motors, feature a more complex rotor structure. The rotor consists of windings placed within slots in a laminated cylindrical core. The ends of these windings are connected to slip rings, which are mounted on the rotor shaft. External resistances can be connected to the rotor circuit via brushes and slip rings, enabling precise control over starting current and torque.

This external resistance is crucial for applications where high starting torque and adjustable speed are necessary, such as cranes, hoists, conveyors, and heavy-duty elevators. Slip ring motors are preferred in settings where load characteristics change frequently or where smooth acceleration is essential for safety and process requirements.

Key Benefits of Slip Ring Motors

- High starting torque for heavy industrial loads

- Speed control and adaptability

- Ideal for variable load applications and heavy machinery

- Facilitates gradual acceleration and deceleration

Applications of 3-Phase Motors

Three-phase motors are the go-to solution for powering a wide variety of industrial, commercial, and even some residential equipment. Their versatility and durability make them a preferred choice for both constant and variable load applications. Understanding typical use cases can guide your selection based on your operational needs.

- Industrial manufacturing—assembly lines, conveyor systems, extruders, mixers, and compressors rely on 3-phase motors for consistent, high-torque power.

- HVAC systems—large fans, blowers, and pumps benefit from the efficiency and reliability of three-phase induction motors.

- Material handling—cranes, hoists, elevators, and escalators often require slip ring motors due to their superior starting torque and speed control.

- Agricultural equipment—irrigation pumps, grain elevators, and feed mixers utilize 3-phase motors for continuous, unattended operation.

- Mining and heavy industry—crushers, grinders, and conveyors demand the robust construction and dependable performance of three-phase motors.

- Water treatment plants—pumps and aerators rely on the energy efficiency and long service life of 3-phase motors.

- Renewable energy systems—wind turbines and hydroelectric generators often use three-phase AC motors for efficient power generation and conversion.

Wondering if a 3-Phase Motor Is Right for Your Application?

Are you unsure whether you need a squirrel cage or slip ring motor for your operation? Compare the torque, speed control, and starting requirements of your application. If you need high starting torque and variable speed, a slip ring motor is often ideal. For reliable, low-maintenance operations, a squirrel cage motor is usually the best choice.

Advantages of 3-Phase Motors

Three-phase motors offer numerous benefits over single-phase motors and other power conversion solutions. These advantages contribute to their dominance in industrial automation and infrastructure projects worldwide.

- Simple, robust construction—fewer moving parts and no commutators mean less downtime and reduced maintenance.

- High efficiency—three-phase induction motors achieve efficiencies up to 95%, lowering operational costs and conserving energy.

- Favorable power factor—reduced losses and improved voltage regulation help meet stringent energy standards.

- Self-starting torque—no need for external starters or complex electronics to initiate operation.

- Stable, non-pulsating power delivery—ensures smooth operation and protects sensitive equipment from power fluctuations.

- Automatic and continuous operation—suitable for automation and 24/7 industrial processes with minimal human intervention.

- Scalability and flexibility—available in a wide range of power ratings, speeds, and mounting configurations to fit any application.

- Long operational lifespan—built to withstand harsh environments and heavy-duty cycles.

Are 3-Phase Motors More Efficient Than Single-Phase Motors?

Yes, three-phase motors are typically more efficient than single-phase motors. They deliver smoother power with less vibration, have higher power density, and are better suited for industrial loads. If you’re considering upgrading from single-phase to three-phase systems, you can expect improved performance and lower total cost of ownership.

How to Choose the Right 3-Phase Motor

Selecting the ideal three-phase electric motor involves evaluating several critical factors, including:

- Load requirements—determine the starting and running torque, speed, and power needed for your equipment.

- Environment—consider exposure to dust, moisture, chemicals, or extreme temperatures and choose appropriate IP ratings and enclosures.

- Control needs—assess whether variable speed drives (VFDs) are required for process flexibility.

- Duty cycle—match the motor rating (continuous, intermittent, or short duty) to your application profile.

- Energy efficiency—look for motors that meet or exceed IE2, IE3, or IE4 efficiency standards to save on operating costs.

- Mounting and size constraints—ensure the motor fits your available space and mechanical interfaces.

- Budget and lifecycle costs—balance initial investment with long-term maintenance and energy savings.

Need Help Sizing or Selecting a 3-Phase Motor?

Explore our industrial motors directory for expert advice, technical datasheets, and application guides. You can also request a quote or consult with a specialist for tailored recommendations.

Choosing the Correct 3-Phase Motor Supplier

To ensure you get the best value and performance from your purchase, it’s vital to compare 3-phase motor suppliers and manufacturers. Leverage our comprehensive directory of 3-phase motor companies to discover industry leaders, innovative technologies, and custom solutions tailored to your requirements.

- Each supplier’s business profile offers detailed information on their capabilities, certifications, and areas of expertise.

- Use our website previewer to evaluate each supplier’s product range, support services, and engineering resources.

- Contact multiple suppliers simultaneously using our streamlined RFQ (Request for Quote) form to compare pricing, lead times, and technical support.

- Assess after-sales service, warranty terms, and spare parts availability for long-term peace of mind.

- Read customer reviews and case studies to gauge satisfaction and real-world performance.

Questions to Ask When Evaluating 3-Phase Motor Suppliers

- What efficiency classes (IE2, IE3, IE4) do your motors meet?

- Do you offer customization for voltage, frequency, speed, or enclosure type?

- What is your lead time for standard and custom orders?

- How do you support installation, commissioning, and maintenance?

- Can you provide references for similar projects or industries?

Frequently Asked Questions About 3-Phase Motors

How do I wire a 3-phase motor?

Wiring a three-phase motor requires a proper connection to a balanced three-phase supply, typically using a star (Y) or delta (Δ) configuration. Always follow manufacturer guidelines and consult a qualified electrician for installation to ensure safety and compliance with electrical codes.

Can a 3-phase motor run on single-phase power?

While it is technically possible to operate a three-phase motor on single-phase power using a phase converter or variable frequency drive (VFD), this is not recommended for critical or high-load applications. Doing so may reduce efficiency and motor lifespan.

How do I control the speed of a 3-phase motor?

Speed control of three-phase motors is commonly achieved with a variable frequency drive (VFD), which adjusts the supply frequency and voltage. This allows for smooth, precise speed variation and energy savings in variable-load applications.

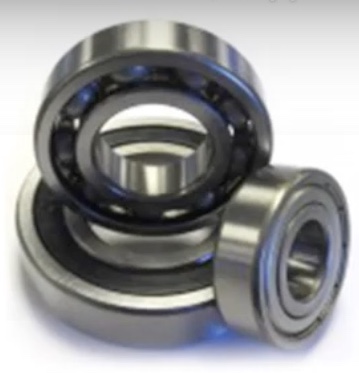

What maintenance do 3-phase motors require?

Routine maintenance typically includes inspecting bearings, checking for abnormal noise or vibration, ensuring clean ventilation pathways, and monitoring electrical connections. Squirrel cage motors require less upkeep than slip ring motors because they lack brushes and slip rings.

What is the lifespan of a 3-phase motor?

With proper installation and regular maintenance, three-phase motors can last 20 years or more in industrial settings. Factors affecting lifespan include operating environment, load profile, quality of power supply, and adherence to recommended maintenance schedules.

Start Your Search for the Best 3-Phase Motor Solution

Ready to upgrade your facility with high-efficiency, reliable three-phase motors? Browse our directory now to find leading manufacturers, compare product specifications, request quotes, and access expert resources. Whether you need a standard squirrel cage motor, a custom slip ring motor, or application-specific engineering support, you’ll find the right solution to maximize productivity and minimize downtime.

Still Have Questions?

Contact us today for expert guidance on selecting, installing, or maintaining your three-phase electric motors. Our team is ready to help you optimize performance, reduce costs, and ensure long-term success in your operations.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

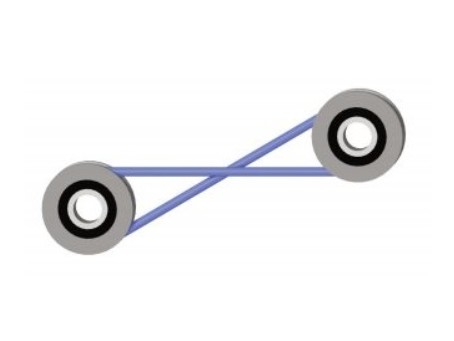

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services